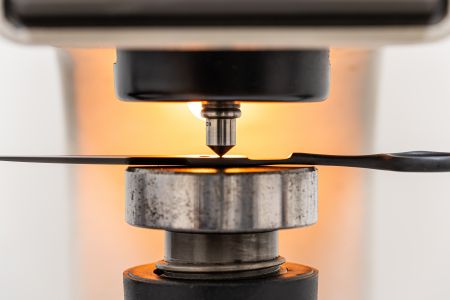

品質管理

皇崟實業股份有限公司是台灣知名的剪刀工廠,我們有嚴格的品質管理,包含壽命測試機、硬度測試機、和3D測量儀。我們工廠通過內部及外部品質稽核,通過ISO 9001認證及UL認證。此外,我們也致力於達到每位客人的最高標準,像是品質控管、製造過程和社會責任標準。

| Test Items | Device Name | Test | The Main Function | Standard Test Conditions | Operating Range |

|---|---|---|---|---|---|

| Hardness | Rockwell hardness machine (AR-10) | Voluntarily | Metal hardness testing | 420J2: HRC 52 ± 2 ° | 1. Measuring force: 60kgf / 100kgf / 150kgf |

| 1. 4034: HRC 57 ± 1 ° | 2. Minimum test thicknes 1mm, the maximum thickness of 115mm test | ||||

| AUS8: HRC 58 ± 1 ° (cryogenic) | 3. Minimum reading: 0.5HR | ||||

| 440C: HRC 60 ± 1 ° (cryogenic) | 4. Measurement Unit: HRA, HRB, HRC | ||||

| Metallurgical structure | Abrasive cutting machines | Voluntarily | Cutting inserts buried analyte into slices | NA | For metal, plastic material cutting |

| Buried inlay machine | Voluntarily | The analyte slices skids for solidification inserts buried into the cylinder | NA | Operating time of about 15 minutes | |

| Buried inlay polishing machine | Voluntarily | The inlay buried polished cut surface of the slice made for metallurgical test | NA | NA | |

| Micro Hardness Tester (FMAR-1) | Voluntarily | 1. Detection of the material surface hardness | 420J2: HRC 52 ± 2 ° | 1. Measurement Unit: HV (convertible HRC) | |

| 2. Observe the cut surface microstructure buried inlay | 1. 4034: HRC 57 ± 1 ° | 2. Metallographic observation magnification: 100X, 400X, 1000X | |||

| 3. The size of the crystalline metallic materials, organizational structure metallographic observation | AUS8: HRC 58 ± 1 ° (cryogenic) | 3. The minimum unit of measure: 0.5HV | |||

| 440C: HRC 60 ± 1 ° (cryogenic) | |||||

| Roughness | Surface roughness tester measure (T1000) | Voluntarily | Surface roughness measurement | Plane grinding: Ra 0.3 ~ 0.6um | 1. The smallest unit: 0.01um |

| Intrados grind: Ra 0.5 ~ 0.6um | 2. Measuring stroke: 16 / 20mm | ||||

| Bevel grinding: Ra 1.0 ~ 1.2um dragging water sand: Ra 0.5 ~ 0.6um | 3. Measurement accuracy: 0.01um | ||||

| 4. Operation range: ± 100um | |||||

| Push, pull | Electronic thrust meter (HF100) | Voluntarily | Push, pull force measurement | Empty paper models cut a level 4 level 8 level Paper Scissors Paper forging <45g <60g <100g <190g | 1. Determination of the unit: N, Kgf (gf) |

| Die Casting <50g <65g <130g <250g | 2. Test Accuracy: ± 0.2% FS | ||||

| A die-cut <60g <75g <160g <270g | 3. Reproduction accuracy: ± 0.1% FS | ||||

| Two die-cut <70g <90g <190g <300g | The response rate: 10 ~ 320 Hz, 6-segment | ||||

| Three scissors | 5. Maximum load: 100N / 10Kgf / 22.04lbf | ||||

| 6. Minimum reading: 0.01N / 0.001Kgf / 0.01lbf | |||||

| Test items | Device Name | Test | The Main Function | Standard Test Conditions | Operating Range |

| Size | 2.5D image measuring instrument | Purchase the middle | 1. Object dimensions (length, width, arc, center distance, depth ..) measurement, to ensure that products meet specifications Dimensions | Drawing on the basis of dimensional tolerances | 1. Measuring stroke: 300mm x 200mm x 150mm |

| 2. Surface imaging test | 3. Repeat accuracy: 0.003mm | ||||

| The smallest unit of measure: 1um | |||||

| 2. Image Magnification: 28X ~ 180X | |||||

| Height measuring instrument | Voluntarily | Object height, thickness measurement | Drawing on the basis of dimensional tolerances | 1. Measuring range: 0 ~ 300mm | |

| 2. Minimum Measurement Unit: 0.01mm | |||||

| Cut life | Life Testing Machine | Voluntarily | 1. Test scissors cut | Forged scissors> 200,000 times a scissors> | 1. Test Range: 0 ~ 10kg |

| 2. scissors cut the number of (life) test | 180,000 times two scissors> | 2. The smallest unit of measurement: 1g | |||

| 150,000 three scissors> 100,000 | 3. Measurement Accuracy: 2g | ||||

| Test hundred cells | 100 grid knives + 3M (# 600) Tape | Voluntarily | Coated surface adhesion test degree | Use a knife hundred cells per cell, then use the 3M # 600 adhesive tear tape, 0 no loss, a loss must be less than 5%, 2 5% to 15% off, 3 from 15 to 35% off. | |

| Heavy metals testing | Inductively coupled plasma atomic emission spectroscopy analyzer | Outsourcing | Test raw ingredients of cadmium, lead, mercury, total chromium ... four major heavy metal content, in order to ensure compliance with RoHS requirements | Cadmium Cd <100ppm, lead Pb <1000ppm, Mercury Hg <1000ppm, hexavalent Cr 6+ <1000ppm | NA |

| Test Items | Device Name | Test | The Main Function | Standard Test Conditions | Operating Range |

| Salt spray test | Salt spray machine | Outsourcing | Verify that the product at high temperature, high humidity, after 72 hours, its quality specifications are met | 5% saline solution in the pH range 6.5 to 7.2, is atomized into mist, a heating cabinet maintained at 35°C --24 ~ 48Hr | Temperature at room temperature ~ 50°C |

| The impact of thermal cycles | Hot and cold impact test machine cycle | Outsourcing | Verify that the product in a very short period of time, from extreme cold to extreme heat, extreme cold lower and lower, after several cycles, the product meets the specifications | 70 degrees 2Hr / -20 degrees 2Hr / 30 cycles / conversion time of 5min 80 degrees 2Hr / -30 degrees 2Hr / 30 cycles / conversion time of 5min | Temperature -60°C ~ 150°C; humidity 10% to 98% |

| High temperature and humidity test | Constant temperature and humidity | Outsourcing | Test products in certain of the environment (temperature and humidity), the next change in the characteristics of the product, and still meet the specifications | Temperature +70 degrees / humidity 90% / 240Hr | Temperature -60°C ~ 150°C humidity 10% to 98% |

| Packaging vibration testing | Vibration testing machine | Outsourcing | Effects of simulated vibration during transportation of the product | Random Mode 5 ~ 55 ~ 5 Hz / 3 axis (x, yz) /0.5G each 30min / displacement 5mm / 10 cycles | Frequency 5 ~ 100Hz, the gravitational acceleration 0.5 ~ 14G, the displacement amount 0.5 ~ 100mm, load 0 ~ 200kg |

| Packaging drop test | Drop test machine | Outsourcing | Impact on product handling process simulation drop | A six-sided prism angle 3 free fall, the 1st, weight <= 9.1kg height 91cm, 9.1 <m <= 18.2kg height 76cm | Height 150cm ~ 5cm |