Quality Assurance

Eversharp is the leading scissors manufacturer in Taiwan and is recognized as a global leader in quality and value. We conduct a strict quality control process including lifetime cycle cutting testing, hardness assurance, and 3D measurement testing.

Eversharp has met and exceeded internal and external audits of quality and manufacturing. We have received external and internal ISO 9001 certification UL audits.

We also strive to meet our clients’ customized requirements, which includes quality system controls, manufacturing processes, and social compliance audits.

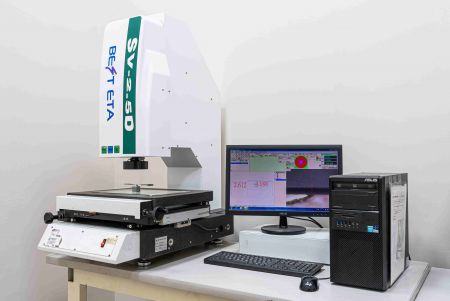

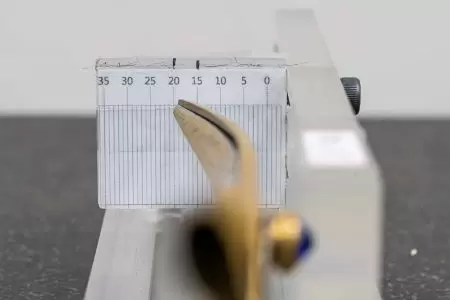

Keyence 3D

The Keyence machine tests all properties of the scissors including curved, angled, and thinner-toothed shapes, using advanced technology for precision and quality. High-resolution scanning verifies dimensional accuracy and detects imperfections in blades and handles, improving manufacturing standards and ensuring reliable, high-performance.

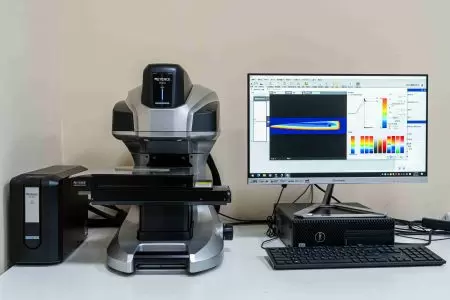

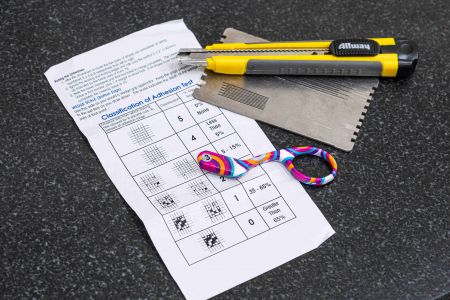

Surface Roughness Gauge

A Surface Roughness Tester is used to ensure cutting edges meet exacting standards. By measuring the surface roughness, this test ensures the blades are smooth and sharp, crucial for precise cutting performance. It helps maintain consistency in manufacturing, identifying any imperfections that could affect functionality or durability.

Final Quality Control

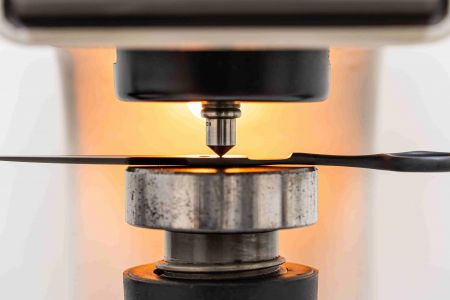

Scissors Lifecycle Testing

Scissors lifecycle testing evaluates durability and performance by simulating extended use, assessing blade sharpness, handle ergonomics, and structural integrity. It ensures optimal cutting efficiency and comfort throughout the product's lifespan, validating reliability under various conditions. This testing helps manufacturers improve longevity, user satisfaction, and adherence to quality standards.

Pet Scissor Sharpness Testing

Testing pet scissor sharpness involves trimming fur/hair to evaluate the scissors' cutting precision and ease. This method ensures the scissors provide smooth, precise cuts without snagging or causing discomfort to the pet, helping maintain effective grooming for the animal's hygiene and comfort.

Hair Simulation Cut Testing for Straight Scissors and Thinners

Testing straight scissor sharpness involves cutting on a hair wig to assess precision and smoothness. This method ensures clean, even cuts without damaging strands. This ensures hairstyling can have confidence in our products for performance and reliability.